HOT LINE: 086-577-65159218

HOT LINE: 086-577-65159218

INDUSTRY NEWS

INDUSTRY NEWS

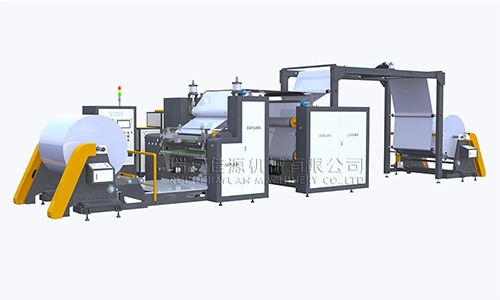

In modern industrial production, the demand for label and tape is growing day by day, and its application scope covers a wide range of fields, including packaging, logistics, medical, electronics, and more. To meet the market's demand for high-quality label and tape, the label and tape coating machine has come into being and become a key piece of equipment in the industry. This article will introduce in detail the characteristics, advantages, and application fields of the label and tape coating machine to help you better understand this advanced production technology.

The label and tape coating machine adopts an advanced coating head and intelligent control system to ensure the uniformity and stability of the adhesive layer. Its coating system can accurately control the amount of adhesive, avoiding the problem of the adhesive layer being too thick or too thin, thereby ensuring the adhesion performance and appearance quality of the tape. This high-precision coating technology not only improves production efficiency but also significantly enhances the market competitiveness of the product.

The label and tape coating machine has achieved a high degree of automation. From the feeding of raw materials, coating, compounding to the winding of finished products, the entire process requires no manual intervention. The automated control system not only improves production efficiency but also reduces the impact of human factors on product quality, ensuring the stability and consistency of the product. This level of automation not only increases production efficiency but also reduces production costs, improving the economic benefits of enterprises.

With the increasing awareness of environmental protection, the environmental characteristics of the label and tape coating machine have made it a favorite in the industry. This equipment uses solvent-free hot melt adhesive, reducing the emission of volatile organic compounds (VOC), which meets the modern environmental requirements. At the same time, its energy-saving design reduces energy consumption, saving production costs for enterprises and contributing to sustainable development.

The label and tape coating machine is not only suitable for traditional paper and film materials but can also achieve high-quality coating effects on a variety of materials. Its flexible coating system and automated control system can meet the needs of different customers, improving the versatility and cost-effectiveness of the equipment. For example, the equipment can be used to produce PVC, PET film, and various composite materials for lamination.

The efficient coating system and automated control system of the label and tape coating machine can significantly improve production efficiency. Its continuous production mode reduces production downtime, ensuring the efficient operation of the production line. Compared with traditional manual coating methods, the production efficiency of the label and tape coating machine has increased several times, greatly reducing the production cycle.

Through precise temperature control and uniform coating system, the label and tape coating machine can ensure the high quality of the tape. Its automated control system reduces the impact of human factors on product quality, ensuring the stability and consistency of the product. High-quality label and tape perform well in adhesion and weather resistance, meeting the needs of different industries.

The high degree of automation of the label and tape coating machine reduces manual intervention, reducing labor costs. At the same time, its efficient production efficiency and energy-saving design further reduce production costs. In addition, the stable operation of the production line reduces equipment maintenance and raw material waste, bringing significant economic benefits to enterprises.

The label and tape coating machine is not only suitable for traditional paper and film materials but can also achieve high-quality coating effects on a variety of materials. Its flexible coating system and automated control system can meet the needs of different customers, improving the versatility and cost-effectiveness of the equipment. For example, the equipment can be used to produce PVC, PET film, and various composite materials for lamination.

Label and tape are widely used in the packaging industry, such as express packages, product labels, etc. Their excellent adhesion and weather resistance can effectively prevent the damage of packages during transportation, ensuring the safe delivery of goods. The label and tape coating machine provides high-quality tape products for the packaging industry, enhancing the sealing performance and appearance of packaging.

In the medical field, label and tape are used for the fixation and protection of medical devices, ensuring the sterility and safety of products. Their excellent adhesion and softness can meet the strict requirements of the medical industry for product safety and reliability. The label and tape coating machine produces high-quality tape, providing a reliable solution for the medical industry.

The manufacturing of electronic devices requires high-precision label and tape to prevent the ingress of dust and moisture. The label and tape coating machine can produce high-quality tape that meets the high-precision requirements of electronic device manufacturing. Their excellent adhesion and weather resistance ensure the reliability and durability of electronic devices.

In automotive manufacturing, label and tape are used for the sealing of car doors, windows, and body joints, effectively reducing noise and vibration, and improving the comfort of the car. The label and tape coating machine produces high-quality tape that meets the strict requirements of the automotive industry for sealing materials, ensuring the sealing performance and durability of the car.

The label and tape coating machine, with its efficient, stable, and environmentally friendly characteristics, provides a reliable solution for the production of label and tape. Its wide application in packaging, medical, electronics, automotive, and other industries demonstrates its strong market potential and application prospects. Choosing the label and tape coating machine can not only improve production efficiency and ensure product quality but also reduce production costs, bringing significant economic benefits to enterprises. In the future development, the label and tape coating machine will continue to innovate and provide stronger support for the development of the industry.

Double Sided Strong Stick enterprises should develop towards the direction of the group

2025-03-22

Production process and environmental characteristics of the linerless label coating machine

2025-03-21

Advantages and Industry Applications of linerless label coating machine

2025-03-19

linerless label coating machine: a force for innovation in label production

2025-03-17

Tel: 086-577-65159218

Email: jaynn@jaynn.com

Add: No.1,Area C,Wandong Intelligent Manufacturing Industrial Park,Zhejiang Province,China.

SUBSCRIBE

Get the latest updates in real-time

Scan WeChat

Scan Tiktok