HOT LINE: 086-577-65159218

HOT LINE: 086-577-65159218

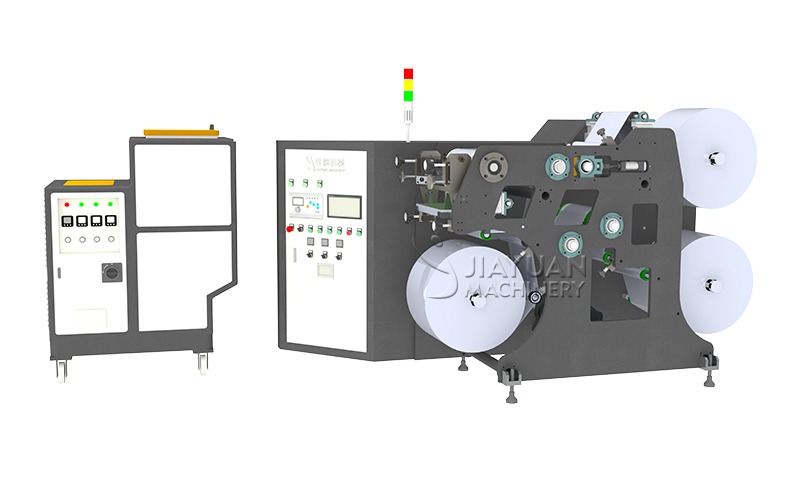

HOT MELT COATING MACHINE

Hot melt adhesive coating machines are applicable to adhesive paper products such as self-adhesive tapes, masking tapes, kraft papers, double-sided tapes, and label papers. They are also used for the adhesion and lamination of non-woven fabrics, cloth bases and other materials in the fields of medical and health, shoe materials, and clothing materials. Hot melt adhesive coating machines can coat hot melt adhesives on different types of substrates such as paper, plastic films, fabrics, and foam materials to achieve functions such as bonding, sealing, reinforcing, or coating. The advantages of hot melt adhesive coating machines include fast coating speed, simple operation, high bonding strength, and suitability for various materials.

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

Read Detail

HIGH-SPEED PRODUCTION

The Hot Melt Coating Machine enables continuous, rapid coating, significantly increasing output and shortening lead times.

PRECISE COATING

Advanced control systems ensure the Hot Melt Coating Machine delivers a uniform coating thickness for consistent, high-quality results.

ENERGY EFFICIENT & ECO-FRIENDLY

With low-temperature processing and no solvents, the Hot Melt Coating Machine reduces energy use and environmental impact.

USER-FRIENDLY OPERATION

An intuitive interface makes the Hot Melt Coating Machine easy to operate and maintain, minimizing training requirements.

WIDE MATERIAL COMPATIBILITY

The versatile Hot Melt Coating Machine handles various substrates and adhesive types for diverse production needs.

ROBUST & RELIABLE

Durable construction ensures the Hot Melt Coating Machine operates stably over the long term, minimizing downtime.

Q: What is a Hot Melt Coating Machine used for?

It applies melted adhesives onto substrates, which then cool to form a solid, functional coating layer.

Q: What are its main benefits?

A key benefit of using a Hot Melt Coating Machine is its solvent-free, eco-friendly operation and fast processing speed.

Q: What industries use this equipment?

Industries like packaging, tapes, and medical products frequently rely on a Hot Melt Coating Machine for production.

Q: How does it ensure coating consistency?

Precise temperature and speed control within the Hot Melt Coating Machine are vital for uniform adhesive application.

Q: What maintenance does it require?

Regular cleaning of the tank and nozzles is essential maintenance for any Hot Melt Coating Machine.

Q: Can it apply different coating patterns?

Yes, by using various applicator heads, a Hot Melt Coating Machine can produce stripes, spirals, or full coverage.

Q: What substrates can it coat?

It can effectively coat paper, film, foil, and non-woven fabrics in a Hot Melt Coating Machine line.

Q: Why is it considered efficient?

The Hot Melt Coating Machine enables high-speed, continuous production with instant bonding and no drying time.

热熔胶涂布机 Plastic Bag Making Machine PDC Sensor Paper Bag Making Machine

Analysis of influencing factors in the production process of hot melt coating machine for label stock sticker IntroductionHot melt coating machines play a crucial role in the production of l...

Hot melt adhesives are widely used in automated packaging, medical and health supplies, logistics, label tapes, automobiles, construction, household daily necessities, shoes, hats, bags and ...

Septemberisthefruitfulandharvestseason,Jiayuanmachineryisalsobusydeliveryingmachine.AnotherHot Melt Coating Machineisreadyto Shandong customers....

Dear Nantong, Jiangsu customers, Your order JYJ type butyl rubber coating equipment has been shipped, Please hurry tidy warehouse, Well prepared to accept the goods.JYJ type butyl rubber coa...

Tel: 086-577-65159218

Email: jaynn@jaynn.com

Add: No.1,Area C,Wandong Intelligent Manufacturing Industrial Park,Zhejiang Province,China.

SUBSCRIBE

Get the latest updates in real-time

Scan WeChat

Scan Tiktok